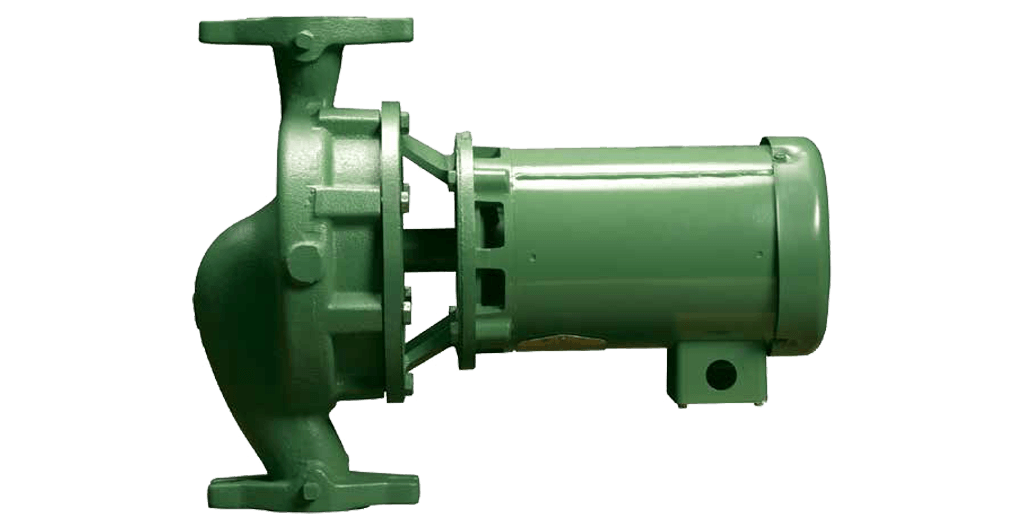

1900 Series Close-Coupled In-Line Pumps

Performance Data

Flow Range: 7 – 280 GPM

Head Range: 6′ – 164′

Working Pressure: 175 PSI in accordance with ASA B16.1

Temperature: 250°F Standard, 300°F with Hi-Temp Seal

HP: ¼ – 7 ½

Sizes: 1 ½”

Features

- Close-Coupled Compact Design is Energy Efficient and Installs Anywhere in the Piping Layout

- Self-Supporting Design Allows Horizontal or Vertical Installation

- Pump and Sealed Ball Bearing Motor are Maintenance-Free

- Rear Pullout Design and Standard Motor Promote Simple, Easy Service

- One Seal and Shaft Sleeve Fits All Models, Assuring Superior Parts Flexibility

Applications

- LoadMatch®Systems

- Air Conditioning Systems

- Recirculation

- Booster Service

- Heating Systems

- Laundry Equipment

- Cooling Towers

- Golf Courses

- Dry Cleaning Plants

- Livestock Watering

- Bottle Washers

- Lawn Sprinklers

Taco Comfort Solutions

Service & Support